The DTH Hammers – K65 produced in Hyderabad represent the fusion of advanced engineering and rugged performance for drilling applications. Designed to deliver powerful penetration, precision, and efficiency, these hammers are trusted by industries such as mining, quarrying, and construction. Their reputation for reliability has made them a leading choice in both domestic and global markets.

Manufacturers in Hyderabad have perfected the art of producing K65 DTH Hammers using cutting-edge manufacturing facilities, stringent quality checks, and innovative designs. This ensures that every unit offers consistent drilling performance across varying geological formations. Whether tackling soft strata or the hardest rock layers, these hammers guarantee dependable results.

From deep borewell projects to complex rock excavation works, the K65 DTH Hammers from Hyderabad combine long-lasting durability with cost-effective operation. Businesses seeking equipment that balances quality, speed, and efficiency find these tools indispensable for heavy-duty drilling needs.

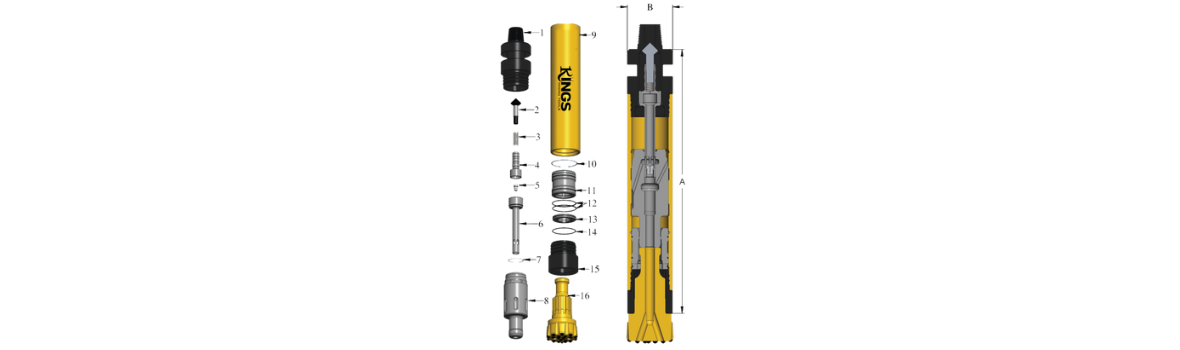

Core Characteristics of Hyderabad-Made K65 DTH Hammers

- High-impact energy for faster drilling in tough conditions

- Optimized airflow design for efficient energy transfer

- Robust alloy steel body for prolonged lifespan

- Quick-change bit system to reduce downtime

- Low back-pressure design for higher productivity

- Adaptable to different rock formations and depths

- Heat-treated components for exceptional strength

Technical Profile of K65 Models

- Hammer Size: 6-inch class

- Bit Shank Type: K65

- Operating Pressure: 100–350 psi (7–24 bar)

- Air Requirement: 500–1000 cfm

- Weight: 120–140 kg (approx.)

- Recommended Drill Pipe OD: 4"–4.5"

- Material: Premium alloy steel with advanced heat treatment

Advantages of Opting for Hyderabad K65 Hammers

- Superior drilling speed for increased project efficiency

- Long service life reducing replacement frequency

- Lower air and fuel consumption for cost savings

- Reliable performance in various geological conditions

- Easy to operate with minimal vibration

- Compatible with most standard drilling rigs

Industry Usage of K65 DTH Hammers

- Mining – Efficient drilling for blasting in mines

- Quarrying – Extraction of granite, limestone, and other hard stones

- Water Well Drilling – Ideal for deep bore applications

- Construction – Foundation, piling, and tunneling work

- Geotechnical Surveys – Rock and soil testing for infrastructure projects

Why Hyderabad’s K65 DTH Hammers Lead the Market

- Modern production technology ensuring precision quality

- Use of high-grade raw materials for extended durability

- Energy-efficient design lowering operational costs

- Tailored solutions for specific drilling requirements

- Proven success in large-scale projects across India and abroad

- Reliable local support and quick spare parts availability

Copyright © KINGS MINING TOOLS 2023. All rights reserved. designed by Tradebizz.in