In the high-demand sectors of mining, quarrying, and infrastructure development, the choice of drilling equipment determines operational success. Among the most trusted solutions, the DTH Hammer – K7 stands as a benchmark in precision drilling and durability. Built for performance in diverse rock formations, this hammer combines strength, speed, and efficiency to deliver exceptional results in every project.

Hyderabad has emerged as a hub for high-quality DTH Hammers – K7 manufacturing, with manufacturers providing reliable solutions that meet both domestic and international drilling requirements. Leveraging advanced manufacturing techniques and stringent quality control, Hyderabad-based suppliers ensure each K65 hammer meets the highest industry standards.

Whether for deep-hole drilling, large-diameter boreholes, or heavy-duty rock excavation, the DTH Hammer – K7 offers the power and endurance required by today’s mining and construction industries. Its robust design and cost-effective operation make it a preferred choice for professionals aiming for consistent performance and reduced downtime.

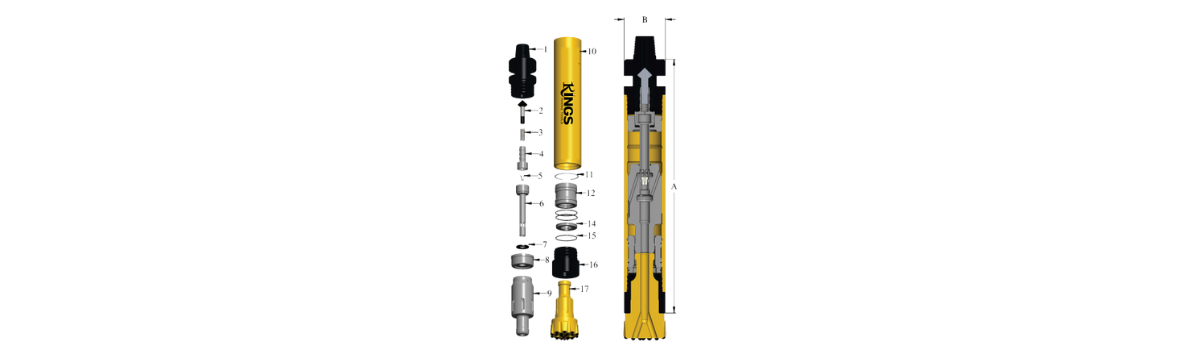

Understanding the K7 Down-The-Hole Hammer

The DTH Hammer – K7 is designed with its impact mechanism positioned directly behind the drill bit, maximizing energy transfer to the rock. This ensures faster drilling speeds, better hole accuracy, and longer tool life. Hyderabad manufacturers tailor these hammers for heavy-duty operations, where both precision and reliability are non-negotiable.

Key Characteristics of the K7 Model

- High-impact force for superior penetration rates

- Optimized airflow for efficient energy usage

- Premium alloy steel body with precision heat treatment

- Low back-pressure for improved compressor efficiency

- Quick and easy maintenance with minimal downtime

- Wear-resistant parts for extended service life

- Compatibility with various bit designs for different drilling conditions

Technical Data and Specifications

- Size Category: 6.5-inch class

- Bit Interface: K65 shank type

- Operating Pressure Range: 100–350 psi (7–24 bar)

- Air Requirement: 700–1000 cfm

- Weight: Approximately 150–180 kg

- Drill Pipe Compatibility: 4.5”–5” OD

- Material: High-grade alloy steel with advanced heat treatment

- Design Availability: Both valve-type and valveless configurations

Benefits of the K7 Hammer

- Delivers high-speed drilling even in challenging rock conditions

- Built for extended operational life with superior materials

- Reduces fuel and air consumption for better cost efficiency

- Minimizes downtime with user-friendly maintenance features

- Adapts to a variety of rock formations and drilling needs

- Maintains consistent output in extreme environmental conditions

Industries and Applications

- Mining: Deep blast holes for open-pit and underground operations

- Quarrying: Precision drilling for stone cutting and blasting

- Water Well Drilling: Large-diameter boreholes for sustainable water supply

- Construction: Foundation and piling drilling for infrastructure projects

- Geotechnical Projects: Core sampling and structural rock analysis

Why the K7 from Hyderabad Manufacturers Excels

- Produced with advanced engineering and premium raw materials

- Airflow optimization ensures efficient energy transfer

- Proven adaptability to different geological conditions

- Easy part replacement reduces repair time

- Supported by local after-sales service and spare parts availability

- Track record of consistent performance in domestic and export markets

Copyright © KINGS MINING TOOLS 2023. All rights reserved. designed by Tradebizz.in